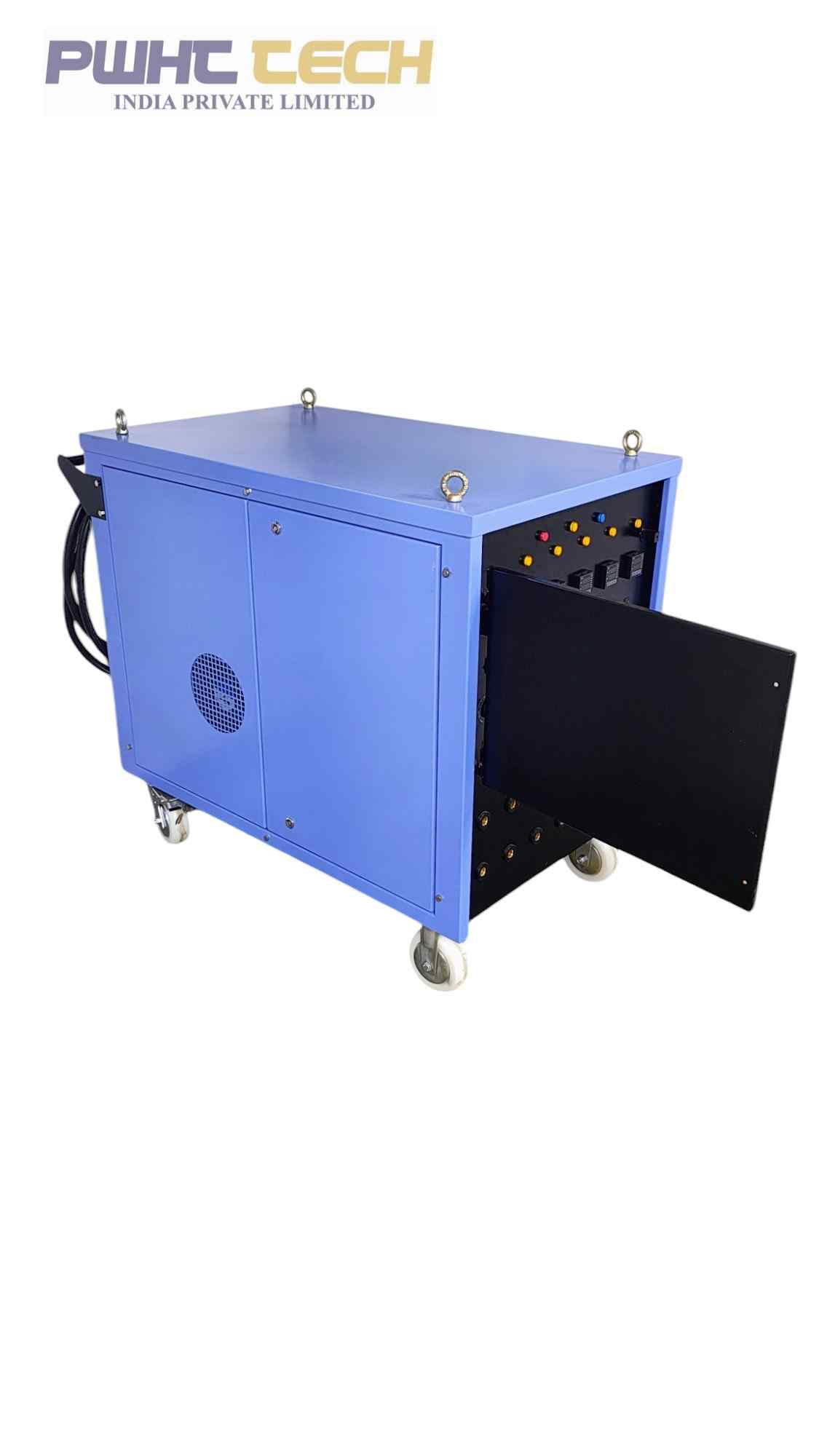

65KVA Heat Treatment Transformer

PART NO: LVHT65K

Precision Heating Solution for Post Weld Heat Treatment (PWHT)

Product Description

The LVHT65K – 65KVA Heat Treatment Transformer is a high-performance, three-phase, air-natural cooled unit engineered for Post Weld Heat Treatment (PWHT) and other industrial heating applications. Designed to provide reliable and precise temperature control, this unit is ideal for onsite projects and fabrication workshops across various industries.

Equipped with six temperature-controlled output channels, each delivering 10.8 kW of power, the LVHT65K efficiently supports up to 24 heating elements (ceramic heater pads). This advanced system offers three operational methods for maximum flexibility:

1. Fully-integrated individual programmers

2. External programmer for all channels

3. Individual proportional energy regulators

With global compatibility and a robust build, this mobile heat treatment unit is perfect for industries requiring consistent and controlled heating, such as oil & gas, shipbuilding, power plants, and heavy steel fabrication.

Contact our support team for further information

+91- 94440 26001

support@pwhttech.com