Key Features:

Traditional Electrical Resistance Method: Utilizes Ceramic Pad Heaters and Ceramic Blankets, controlled by step-down transformers, for a proven heat treatment process that is reliable and efficient.

Twelve Output Channels: Each channel delivers 8.3 kW, capable of powering three 2.7 kW ceramic pads, offering substantial capacity for large-scale heat treatment projects.

Flexible Heat Control: Choose from three operational methods: fully-integrated individual programmers, an external programmer for all channels, or individual proportional energy regulators, offering control and customization.

Mobile and Durable: Designed for both on-site and fabrication shop use, the LVHT100K is portable and robust, built to withstand demanding industrial conditions.

Multi-Application: Ideal for preheating, PWHT, and tempering metal, this equipment helps improve microstructure, reduce tensile stresses, and prevent cracking, ensuring enhanced durability and material integrity.

Global Availability: Available for worldwide supply, this equipment serves industries across the globe with its reliable, high-performance heat treatment capabilities.

Marketing Content:

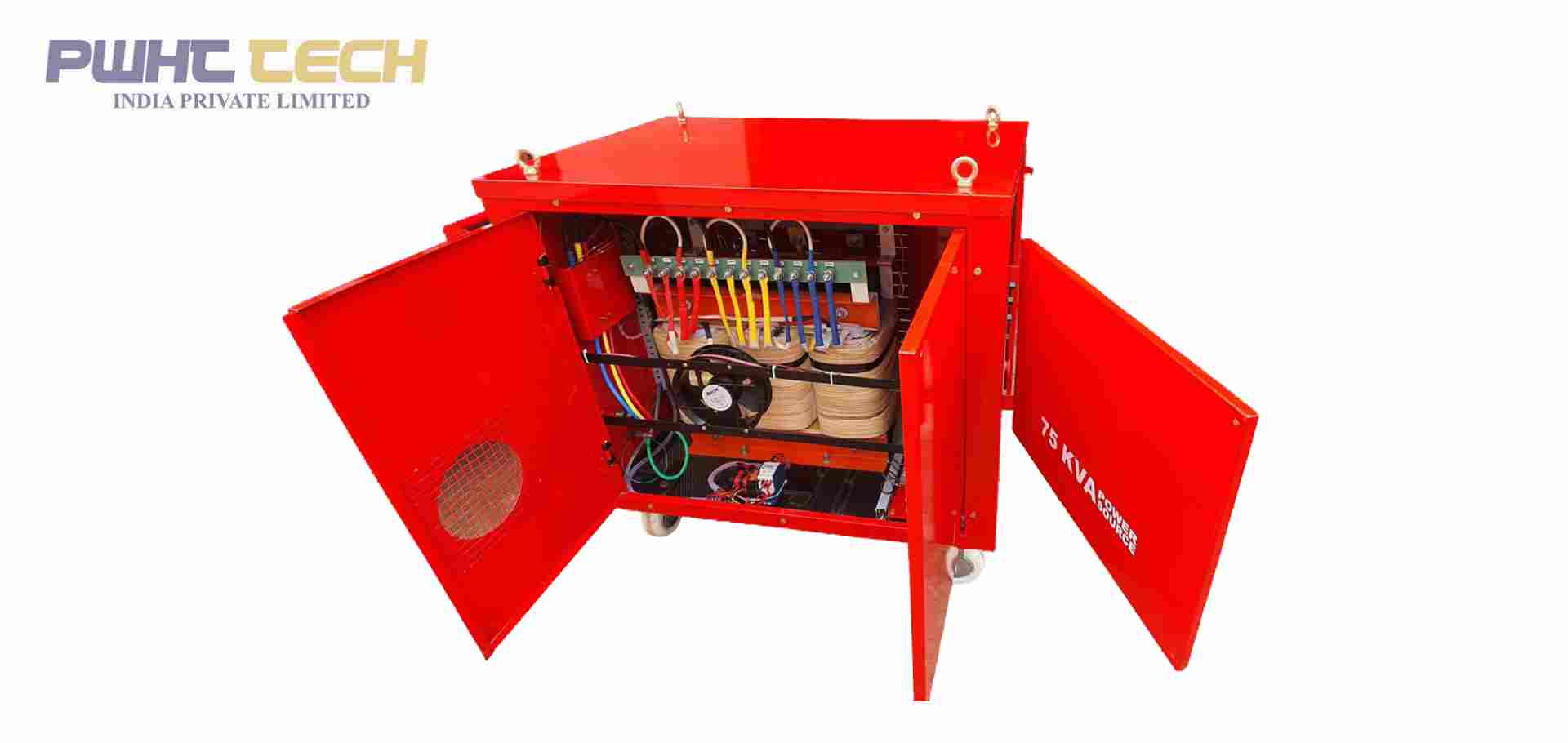

Reliable and High-Capacity Heat Treatment for Industrial Applications

The LVHT100K 100KVA Heat Treatment Equipment is engineered to provide precise and reliable heat treatment for various industrial applications, especially Post Weld Heat Treatment (PWHT). With a high-power capacity of 100kVA and twelve output channels, this equipment ensures that even the most demanding heat treatment tasks are handled efficiently.

Versatile and Flexible Control for Optimal Performance

Designed to handle large-scale heat treatment projects, the LVHT100K offers three flexible operational methods, allowing you to control heat treatment conditions with precision. Whether using integrated individual programmers, external programmers for all channels, or proportional energy regulators, this equipment provides the versatility needed to match the specific requirements of your project.

Durability and Mobility for On-Site and Shop Use

Built for industrial use, the LVHT100K is a mobile unit that can be easily transported to various job sites. Its robust design, including a mild steel case with powder coating, ensures durability even in the toughest conditions. Whether you’re on-site or in the fabrication shop, this equipment delivers consistent and reliable heat treatment results.

Enhanced Performance and Safety

With 65V AC secondary output, 300A panel-mounted connectors, and integrated safety features such as over-temperature sensors and an MCCB protection circuit, the LVHT100K offers both high performance and safety for your heat treatment operations. The equipment is capable of powering up to 36 ceramic heating elements, providing the necessary heat distribution for complex treatments.

Global Availability for Worldwide Operations

Our LVHT100K Heat Treatment Equipment is available for global supply, serving a wide range of industries around the world. Whether you’re working in oil & gas, aerospace, construction, or heavy manufacturing, this equipment offers a dependable solution for improving weld integrity, reducing stress, and enhancing material properties.

Energy-Efficient and Cost-Effective

The LVHT100K maximizes energy efficiency by distributing power evenly across multiple channels, minimizing energy wastage. The ability to control temperature precisely ensures optimal heat application, reducing operational costs while achieving high-quality results.